DCPD Modifier For Heat-Resistant Elastomers

Brand Minghao

Product origin Linyi, Shandong

Delivery time 10-15 days

Supply capacity 3000 tons

DCPD modifiers elevate elastomer heat resistance, ideal for aerospace and automotive components exposed to extreme temperatures.

Parameter

Name | Dicyclopentadiene |

Synonyms | 1,3-Dicyclopentadiene; DCPD 3a,4,7,7a-Tetrahydro-1H-4,7-methanoindene |

CAS | 77-73-6 |

Chemical formula | C10H12 |

Molecular mass | 132.20 |

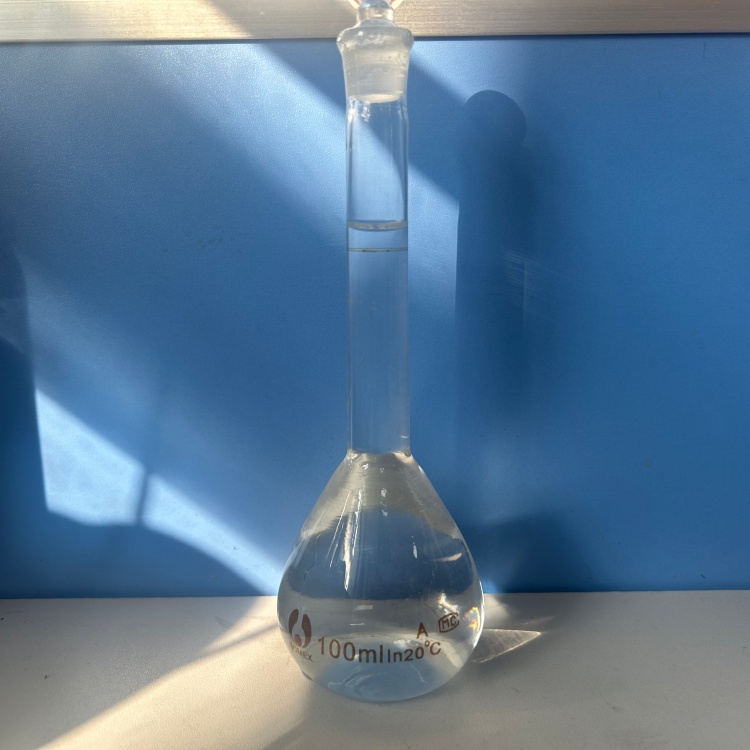

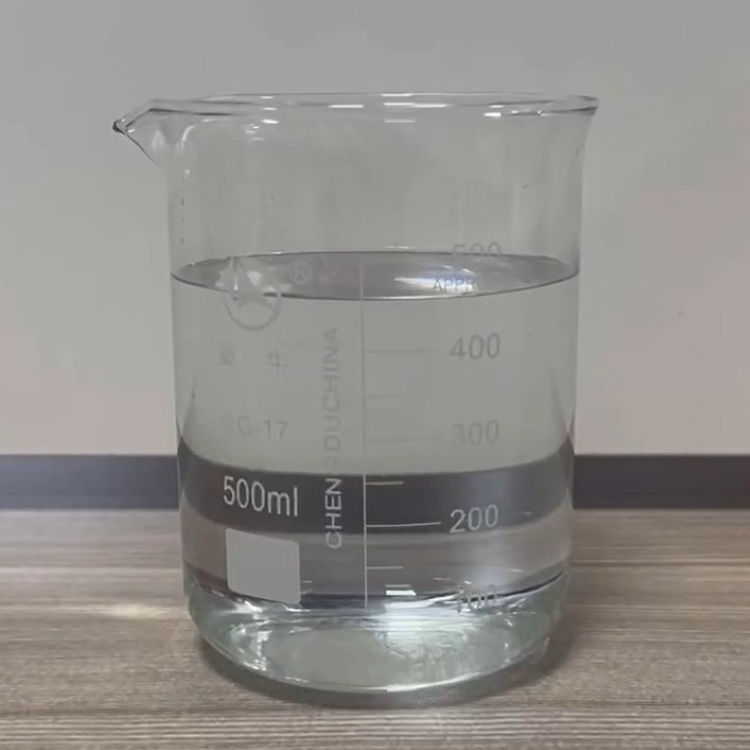

Appearance | Colorless transparent liquid |

Melting point | 32.9℃ |

Boiling point | 166.0℃ |

Density | 0.976(35℃) |

Test items | Mass percentage (%) |

Cyclopentadiene | 0.04 |

Between methylcyclopentadiene and dicyclopentadiene | 0.67 |

Dicyclopentadiene content | 98.58 |

Between dicyclopentadiene and methylcyclopentadiene dimer | 0.28 |

Methylcyclopentadiene dimer | 0.43 |

Water content (ppm) | 96.6 |

Color/(platinum-cobalt) | 15 |

Purpose

Dicyclopentadiene (DCPD) is a versatile chemical raw material widely used in multiple industries. It serves as a key component in the production of synthetic rubber, where it acts as a DCPD modifier for elastomers, significantly enhancing the elasticity and durability of rubber products. Specifically, DCPD is utilized as a DCPD modifier for heat-resistant elastomers, enabling these materials to withstand high temperatures, which is critical for automotive and industrial applications. Beyond rubber, DCPD is employed in the manufacture of pesticides, medicines, synthetic resins, paints, and coatings, leveraging its properties as a DCPD modifier. After hydrogenation, DCPD can be converted into a high-energy fuel, further showcasing its utility. The role of DCPD as a DCPD modifier for elastomers is vital for advancing material performance, while its application as a DCPD modifier for heat-resistant elastomers underscores its importance in developing high-performance materials for demanding environments.

Packaging

Iron Drum, Net Weight 193KG/barrel

IOS Tank

Storage and Transport

Storage: To preserve the quality of DCPD for its critical role as a DCPD modifier for elastomers, it should be stored in a cool, ventilated warehouse, away from fire and heat sources to prevent degradation. DCPD must be kept separate from oxidants, acids, alkalis, and edible chemicals, avoiding mixing to maintain its effectiveness as a DCPD modifier for heat-resistant elastomers. Large-scale or long-term storage should be avoided to ensure its performance as a DCPD modifier. The storage area must use explosion-proof lighting and ventilation facilities, and mechanical equipment or tools prone to sparks are prohibited to prevent fires that could compromise DCPD's utility as a DCPD modifier for elastomers. Equipping the storage area with appropriate materials to contain leaks is essential to safeguard DCPD's integrity for its role as a DCPD modifier for heat-resistant elastomers.

Transport: During transportation, vehicles carrying DCPD, which is vital as a DCPD modifier for elastomers, should be equipped with fire-fighting and leakage emergency treatment equipment. To maintain its quality as a DCPD modifier for heat-resistant elastomers, DCPD is best transported in the morning and evening during summer to avoid high temperatures. Tank trucks should have grounding chains and perforated partitions to reduce static electricity, ensuring safe transport of DCPD as a DCPD modifier. Mixing with oxidants, acids, alkalis, or edible chemicals is strictly prohibited to preserve its functionality as a DCPD modifier for elastomers. DCPD should be protected from sun, rain, and high temperatures during transport, and when stopping, it must be kept away from fire, heat sources, and high-temperature areas to maintain its effectiveness as a DCPD modifier for heat-resistant elastomers. The vehicle's exhaust pipe must have a fire-retardant device, and spark-prone equipment for loading and unloading is prohibited. DCPD release during railway transportation is forbidden, and wooden or cement ships must not be used for bulk transportation to ensure its quality as a DCPD modifier for elastomers.

Pictures

Our Advantages

1. Continuous Innovation: We focus on innovation, leveraging cutting-edge technologies and equipment to stay competitive in the market.

2. Stringent Quality Control: Every product undergoes rigorous quality testing to guarantee consistency and excellence before it reaches our customers.

3. English-Speaking Customer Support: Our dedicated customer service team offers English-language assistance to support our international clients.

4. Sustainable Production Practices: We follow strict safety and environmental standards to promote sustainable and eco-friendly production methods.

5. Proven Track Record: With a history of successful projects and satisfied customers, we have earned a solid reputation in the chemical industry.

Patent Certificates

Packing & Shipping

FAQ

Q: Can you provide detailed specifications for your products, such as chemical composition and applications?

A: Yes, detailed product specifications, including chemical composition and applications, can be provided upon request. Please contact our sales team for more information on specific products.

Q: How can I obtain safety data sheets (SDS) for your products?

A: Safety data sheets (SDS) are available upon request for all our products. Please contact our sales or technical support team to receive the SDS for the specific product you are interested in.

Q: How do you guarantee the quality of your products?

A: Quality is our priority. We enforce strict quality control throughout production and provide certificates of analysis (COA) with every shipment. Goods are tested before delivery to ensure they meet high standards.

Q: How can I confirm product quality before ordering?

A: You can request free samples for testing or review our product certificates. We can also manufacture products according to your specific requirements to ensure satisfaction.

Q: What are your delivery times?

A: Generally, delivery takes 10 to 15 days after receiving your advance payment, depending on the items and order quantity. Contact us for a precise estimate.