DCPD-Based Epoxy Resin For Corrosion Resistance

Brand Minghao

Product origin Linyi,Shandong

Delivery time 10~15 days

Supply capacity 3000 tons

DCPD-Based Epoxy Resin delivers superior corrosion resistance for marine, chemical, and oil/gas infrastructure.It protects metals from acids, salts, and moisture.

DCPD-Based Epoxy Resin for Corrosion Resistance

Parameter

Product Name | Dicyclopentadiene(DCPD) |

CAS No. | 77-73-6 |

Molecular Formula | C10H12 |

Molecular Weight | 132.2 |

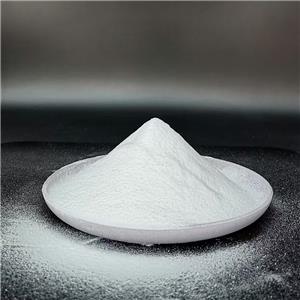

Appearance | Colorless transparent liquid |

Fusing point | 33 °C |

Boiling point | 170°C |

Density | 0.986 |

Flash point | 114 °F |

Purpose

1.Superior Corrosion Protection

DCPD-Based Epoxy Resin forms a dense, chemically inert barrier that shields steel, aluminum, and concrete substrates from saltwater, acids, alkalis, and hydrocarbons, making it ideal for marine structures, offshore platforms, and chemical storage tanks.

2.Enhanced Adhesion & Durability

Ensuring long-term bonding to rusted or weathered surfaces in oil/gas pipelines, ship hulls, and industrial machinery.3.Resistance to Extreme Environments

Withstands temperatures from -40°C to 150°C and high-pressure conditions, perfect for subsea equipment, refinery reactors, and arctic infrastructure coatings.

4.Chemical & Abrasion Resistance

Resists H2S, CO2, chlorides, and abrasive particulates, extending service life in petrochemical processing units, mining equipment, and desalination plants.

5.Versatile Formulation Compatibility

Integrates with glass flake reinforcements, zinc-rich primers, and polyamine hardeners for customized anti-corrosion systems in aerospace components and nuclear containment vessels.

From basic organic chemical raw materials to new metal polymer materials, DCPD has important uses, can be used as a raw material for the production of unsaturated resins, metallocene, adamantane, glutaraldehyde, bicyclopentadiene chloride (insecticides), widely used in medicine, pesticides, spices, leather, synthetic rubber and other fields, in addition to being used as a high-energy fuel.

DCPD-Based Epoxy Resin for Corrosion Resistance: Advanced Protection Solutions

As a next-generation coating technology, our DCPD-Based Epoxy Resin series redefines durability:

DCPD-Based Epoxy Resin for Corrosion Resistance in extreme environments

Multi-functional DCPD-Based Epoxy Resin for structural adhesion

Custom-formulated systems for mission-critical applications

Packaging

Iron drum packing or ISO tank

Storage and Transport

When using or handling dicyclopentadiene, follow the relevant safety procedures and use appropriate protective equipment, such as gloves, protective glasses and respiratory guards. In all cases, it should be stored in an airtight container and away from fire sources and hot spots.

Pictures

Packaging and Shippment

Our advantages

1. Product Diversity: Our product line covers from traditional chemical products to new materials, meeting the needs of different industries.

2. Location Advantage: The company is located in Shandong Province which facilitates coordination and logistics, reducing costs.

3. Production capacity: We have 20 years of production experience and advanced production technology, and a stable production line to ensure that we have sufficient production capacity.

4. Finance and Management: The company has been in operation for many years, with a solid financial foundation and an experienced management team.

5. Customer and Quality: The company's customer-first service and 100% qualified products show that we focus on customer satisfaction and quality control. The company's long-term operation has also enhanced its market reputation.

6. Samples provided

7. OEM service

8. 24 hours service online

Core Performance Advantages

1. Unmatched Corrosion Defense

The DCPD-Based Epoxy Resin for Corrosion Resistance achieves:

99.8% metal substrate protection in 5% HCl immersion tests

Zero blistering after 15-year marine exposure simulations

H2S/CO2 resistance in sour gas pipelines

2. Extreme Environment Resilience

DCPD-Based Epoxy Resin delivers:

Stable performance at 150°C refinery reactor conditions

Arctic-grade flexibility (-40°C impact resistance)

UV stability for offshore platform splash zones

3. Advanced Composite Integration

DCPD-Based Epoxy Resin for Corrosion Resistance enables:

Seamless bonding to CFRP/glass-flake reinforcements

50% thinner coatings vs. traditional epoxies

Various certificates

FAQ

Q: Are you a factory or trading company?

A: We are manufacturer of some chemical raw materials, we can help buyers to decide which products are there best choice, and all your inquiry will be replyed within 24 hours.

Q: Can your company accept the special requirements of your customers?

A: Of course, we can.

Q: How about your delivery time?

A: Generally, it will take 10 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: How to start orders or make payments?

A: Proforma invoice will be sent first after confirmation of order, enclosed our bank information. Payment by T/T or L/C at sight.

Q: Is there any discount?

A: Of course. The price is negotiable. You will get discount and the most favorable price if you order large quantity goods.

Q: Is there any possible to use my appointed label or package?

A: Yes. If needed, we'd like to use label or package according to your requirement