Cyclopentyl Methyl Ether As Plasticizer In Polymer Production

Brand Minghao

Product origin Linyi, Shandong

Delivery time 10-15 days

Supply capacity 10000 tons

Cyclopentyl methyl ether acts as a non-toxic plasticizer, enhancing polymer processability without compromising thermal stability.

Parameter

Name | Cyclopentyl Methyl Ether | |

Synonyms | Methoxycyclopentane; Cyclopentane, methoxy-; | |

CAS | 5614-37-9 | |

Chemical formula | C6H12O | |

Molecular mass | 100.16 | |

Melting point | -140℃max | |

Boiling point | 106℃ | |

Density | 0.86 g/cm3 | |

Explosion limit | 1.1-9.9% | |

| ||

Test items | Standard | Results |

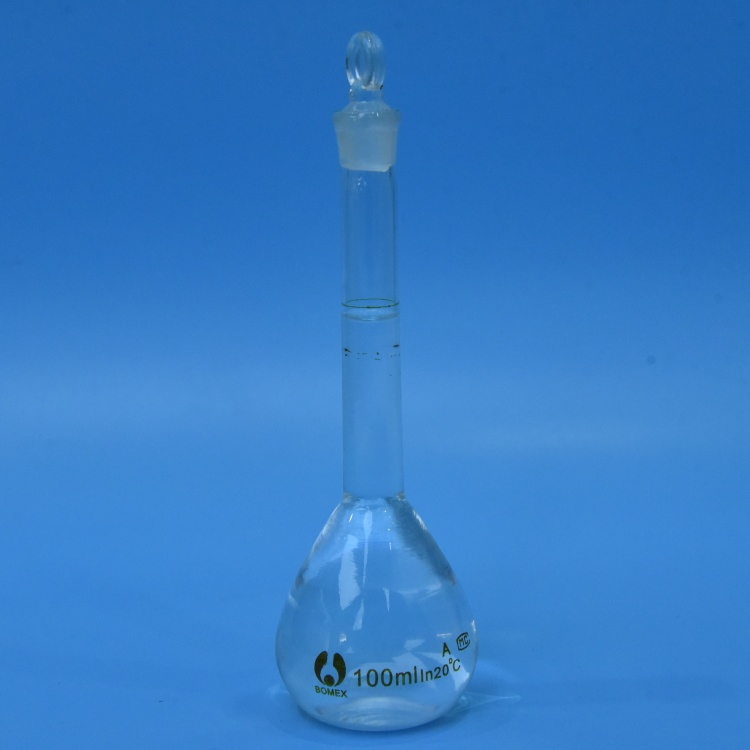

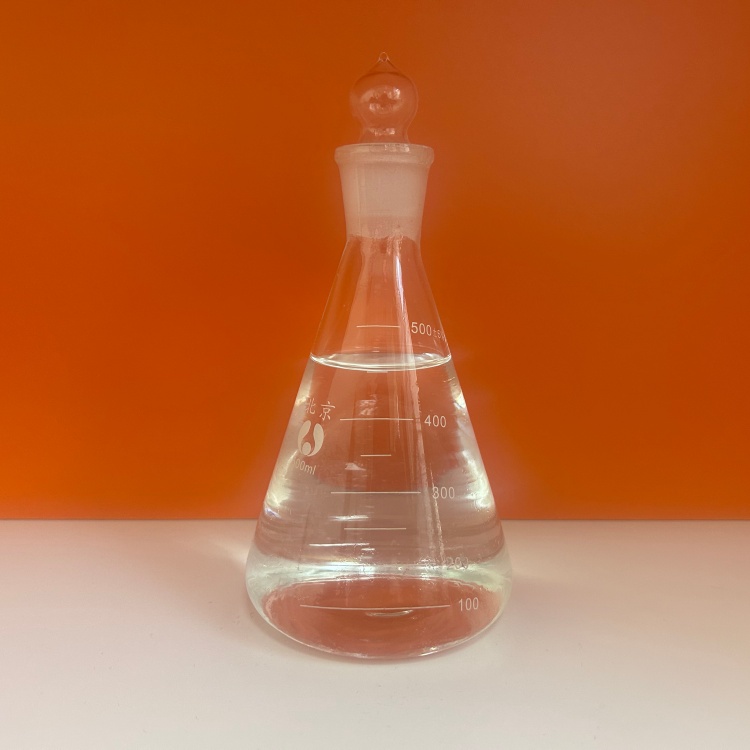

Appearance | Colorless clear liquid | Colorless clear liquid |

Chromatographic purity by GC (% Area) | 99.5min | 99.91 |

Benzene content by GC (%w/v) | 0.02max | Not Detected |

Water content(%w/v) | 0.5max | 0.0045 |

Purpose

Cyclopentyl methyl ether is a versatile solvent with a wide range of applications in chemical processes, notably as a cyclopentyl methyl ether plasticizer that enhances material flexibility. It is extensively used as a reaction solvent in various reactions, including Grignard reaction, Suzuki coupling reaction, Buchwald amination, metal reduction (NaBH4, LHA reduction, i-Bu2, AlH reduction), reactions using n-BuLi, reactions using Lewis acid, and Friedel-Crafts reaction, where cyclopentyl methyl ether plasticizer aids in stabilizing reaction intermediates. Additionally, it serves as an extraction solvent, leveraging its properties as a cyclopentyl methyl ether plasticizer to improve separation efficiency. As a recrystallization solvent, cyclopentyl methyl ether as plasticizer in polymer production ensures high-purity crystals, particularly in polymer-related applications. It is also employed as a polymerization solvent, where cyclopentyl methyl ether as plasticizer in polymer production facilitates the production of flexible and durable polymers. Furthermore, cyclopentyl methyl ether is used as a coating solvent for resins, benefiting from its role as a cyclopentyl methyl ether plasticizer to improve coating adhesion and flexibility. The use of cyclopentyl methyl ether as plasticizer in these processes underscores its importance in chemical and material sciences, particularly in enhancing polymer properties through cyclopentyl methyl ether as plasticizer in polymer production.

Packaging

Iron Drum, Net Weight 170KG/barrel

IOS Tank

Storage and Transport

Proper storage of cyclopentyl methyl ether is critical to maintain its effectiveness, especially as a cyclopentyl methyl Ether plasticizer in sensitive applications. It should be stored in a cool, dry place away from light to preserve its quality as cyclopentyl methyl ether as plasticizer. Containers must be kept tightly closed in a dry, well-ventilated place to prevent degradation that could affect its performance as cyclopentyl methyl ether as plasticizer in polymer production. Opened containers of cyclopentyl methyl ether plasticizer must be carefully resealed and stored upright to avoid leakage, which is vital for maintaining its integrity in cyclopentyl methyl ether as plasticizer applications. Cyclopentyl methyl ether is sensitive to light and air, necessitating careful handling and storage under inert gas conditions to ensure its stability as cyclopentyl methyl ether as plasticizer in polymer production. These precautions are essential to safeguard its functionality as a cyclopentyl methyl ether plasticizer, particularly in polymer production where cyclopentyl methyl ether as plasticizer enhances material properties. By adhering to these storage guidelines, the quality of cyclopentyl methyl ether as plasticizer in polymer production is preserved for optimal performance in industrial applications.

Pictures

Our Advantages

1. Over a Decade of Industry Experience: Established in 2012, we bring more than 10 years of specialized expertise in the petrochemical and fine chemical industries.

2. Safety and Quality Certifications: We are recognized as a secondary safety standardization unit and a city-level benchmark enterprise for dual systems, ensuring top-tier safety and quality.

3. Flexible Payment Options: We accommodate international clients with multiple payment methods, including T/T, and L/C.

4. Transparent Pricing Policy: We provide clear and competitive pricing based on current market conditions, fostering trust with our clients.

5. Proven Track Record: With a history of successful projects and satisfied customers, we have earned a solid reputation in the chemical industry.

Patent Certificates

Packing & Shipping

FAQ

Q: What types of chemical products does your company offer?

A: Our company specializes in petrochemical and fine chemical products.

Q: What factors influence the pricing of your chemical products?

A: Pricing is influenced by several factors, including the type and quantity of the product, raw material costs, production complexity, and market demand. For precise pricing, please request a quote tailored to your specific needs.

Q: How can I obtain safety data sheets (SDS) for your products?

A: Safety data sheets (SDS) are available upon request for all our products. Please contact our sales or technical support team to receive the SDS for the specific product you are interested in.

Q: Can I get samples of your products?

A: Yes, we offer free samples for our products, which can be delivered within 15 days. Please reach out to our sales team to confirm availability.

Q: How can I contact you?

A: Reach us through our website’s contact form, email, phone, WhatsApp, or Trade Manager. All inquiries receive a reply within 24 hours. Visit our Contact page for more details.