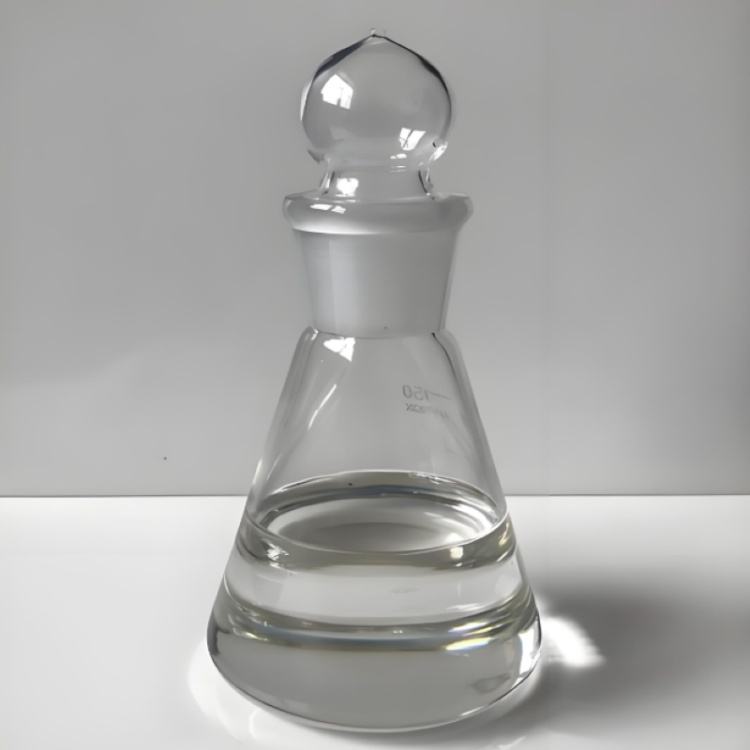

Cyclopentanol For Ketone Derivative Synthesis

Brand Minghao

Product origin Linyi, Shandong

Delivery time 10-15 days

Supply capacity 5000 tons

Leveraging cyclopentanol's reactive hydroxyl group, manufacturers synthesize diverse ketone derivatives for agrochemicals and specialty chemicals with precision. Such as cyclopentanol for ketone derivative synthesis.

Parameter

Name | Cyclopentanol | |

Synonyms | CYCLOPENTYL ALCOHOL; Hydroxy-cyclopentane | |

CAS | 96-41-3 | |

Chemical formula | C5H10O | |

Molecular mass | 86.13 | |

Melting point | -19℃ | |

Boiling point | 140.4℃ | |

| ||

Test items | Standard | Results |

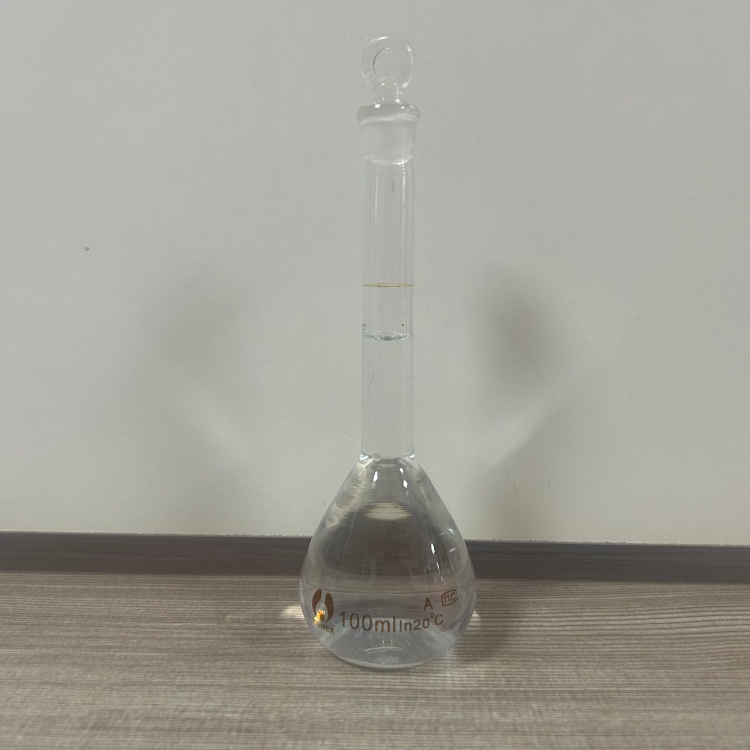

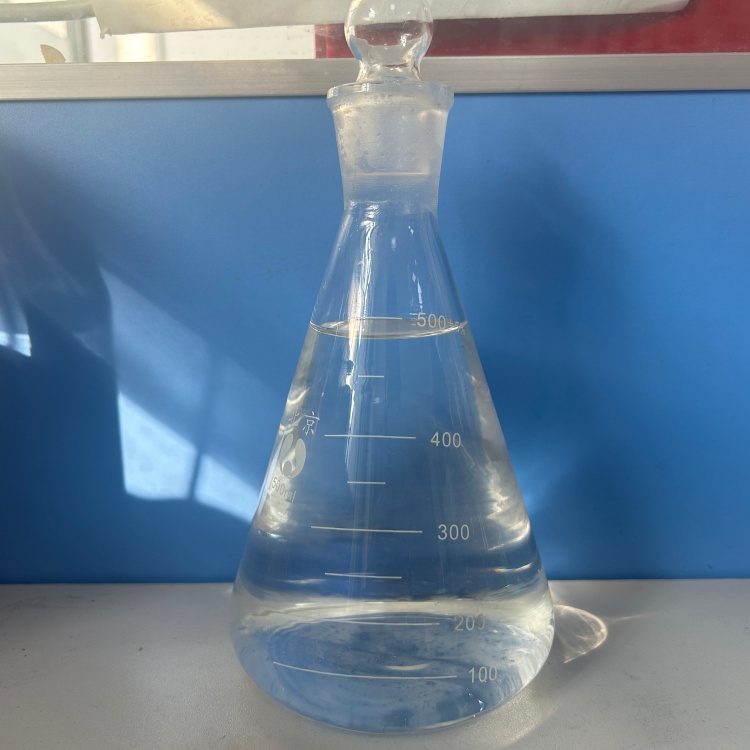

Appearance | Colorless transparent liquid | Colorless transparent liquid |

Cyclopentanol content %(m/m) | 99.0min | 99.42 |

Water content% (m/m) | 0.5max | 0.09 |

Density (g/ml) | 1.004 | 1.000 |

Purpose

Cyclopentanol for ketone derivative synthesis.

Cyclopentanol for synthesis like cyclopentyl alcohol used as an organic synthesis intermediate, used in the production of medicines, dyes and spices, and also as a solvent for medicines and spices.

Packaging

Iron Drum, Net Weight 198KG/barrel

IOS Tank

Storage and Transport

Storage precautions: As cyclopentanol for synthesis, it should be stored in a cool, ventilated warehouse. Keep away from fire and heat. The temperature of the reservoir should not exceed 30℃. Keep the container sealed. Cyclopentanol for synthesis should be stored separately from oxidizer, do not mix storage. Explosion-proof lighting and ventilation facilities are adopted. Do not use mechanical equipment and tools that are prone to spark. The storage area of cyclopentanol for synthesis should be equipped with leak emergency treatment equipment and suitable containment materials.

Transportation precautions: As cyclopentanol for ketone derivative synthesis, the packaging should be complete and the loading should be secure. During transportation, it is necessary to ensure that the container does not leak, collapse, fall or damage. It is strictly prohibited to mix with oxidants, acids, alkalis, food chemicals, etc. Vehicles transporting cyclopentanol for synthesis should be equipped with the appropriate variety and quantity of fire equipment and leakage emergency treatment equipment. During transportation, it should be protected from sunlight, rain and high temperature. Road transport should follow the prescribed route, do not stay in residential areas and densely populated areas.

Pictures

Our Advantages

1. Customized Solutions: We offer tailored products and services to address the specific requirements of our clients, ensuring their satisfaction.

2. International Trade Expertise: Our experienced team manages all international trade documentation and compliance, ensuring seamless customs processes.

3. Sustainable Production Practices: We follow strict safety and environmental standards to promote sustainable and eco-friendly production methods.

4. Proven Track Record: With a history of successful projects and satisfied customers, we have earned a solid reputation in the chemical industry.

5. Free Sample Service: We provide free samples for many of our products, allowing clients to assess quality prior to making a purchase.

Patent Certificates

Packing & Shipping

FAQ

Q: What quality control measures do you have in place to ensure product consistency and safety?

A: We implement strict quality control processes throughout production, relying on advanced technologies and industrialized equipment to ensure product consistency and safety. Our commitment to innovation and operational efficiency further supports our quality assurance.

Q: How can I request a quote for your products?

A: To request a quote, please contact our sales team via the contact form on our website or through the provided email and phone channels. Be sure to include details about the products and quantities you are interested in.

Q: Can I get samples of your products?

A: Yes, we offer free samples for our products, which can be delivered within 15 days. Please reach out to our sales team to confirm availability.

Q: What payment methods are available?

A: We accept T/T, L/C, and PayPal. Choose the option that best suits your needs, and our sales team will assist you.

Q: Why might the quoted price differ from the listed price?

A: Chemical prices fluctuate with market conditions. We aim to provide competitive and transparent pricing based on current market trends.