Cyclopentanol-Based Polyurethane Adhesive Coating

Brand Minghao

Product origin Linyi,Shandong

Delivery time 10~15 days

Supply capacity 5000 tons

Cyclopentanol-Based Polyurethane Adhesive Coating offers eco-friendly bonding with bio-derived cyclopentanol, ensuring high adhesion, thermal stability, and flexibility.

Cyclopentanol-Based Polyurethane

Parameter

Product Name | Cyclopentanol | |

CAS No. | 96-41-3 | |

Molecular Formula | C5H10O | |

Molecular Weight | 86.13 | |

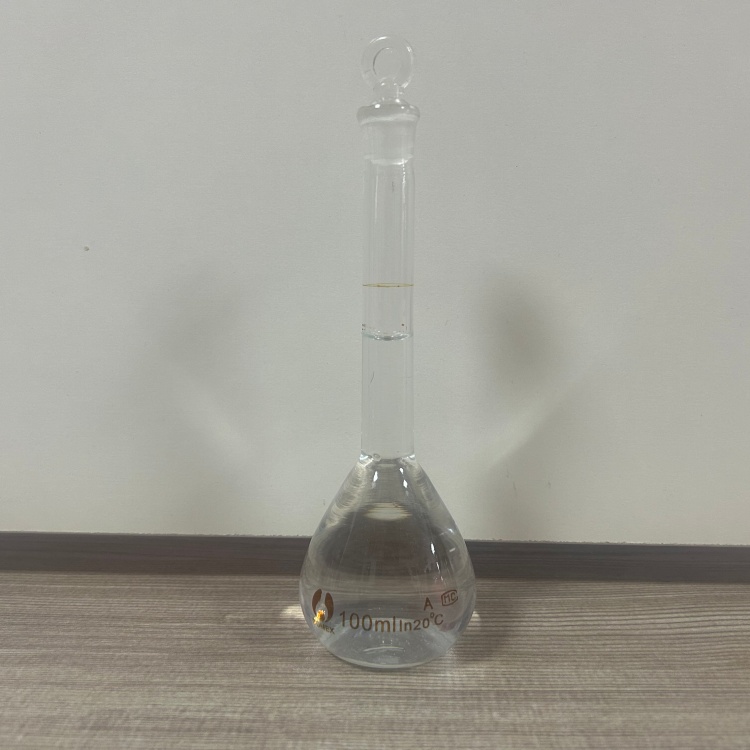

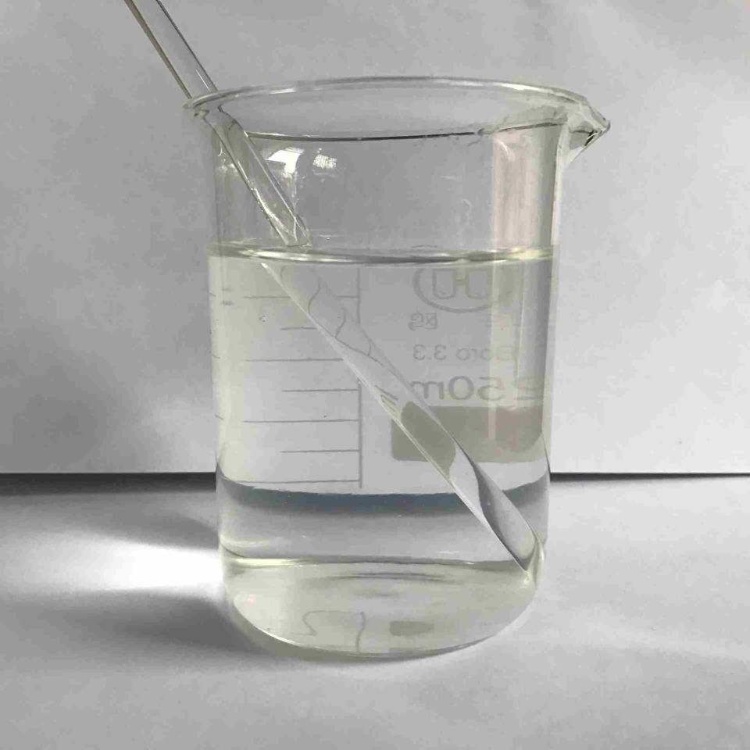

Appearance | Colorless transparent liquid | |

Fusing point | -19 °C | |

Boiling point | 140.4°C | |

Density | 0.95 | |

Flash point | 51 °C | |

Test item | Specification | Test report |

Purity %(m/m) | 99min | 99.37 |

Water content %(m/m) | 0.5max | 0.09 |

Purpose

1.Bio-Derived Sustainability

Formulated with bio-based cyclopentanol, Cyclopentanol-Based Coating reduces reliance on petrochemicals, aligning with circular economy and green chemistry initiatives.

2.Exceptional Bonding Strength

Cyclopentanol-Based Coating delivers high adhesion to metals, plastics, and composites, ideal for automotive interiors, aerospace panels, and sustainable packaging laminates.

3.Thermal & Chemical Resistance

Maintains integrity under extreme temperatures (-40°C to 150°C) and resists oils, solvents, and UV degradation for industrial machinery coatings and outdoor equipment.

4.Flexible Durability

Retains elasticity under stress, perfect for textile-to-rubber bonding in sportswear and vibration-resistant seals in electronics.Cyclopentanol-Based Adhesive Coating.

5.Fast-Curing Efficiency

Optimizes production speed in high-volume manufacturing (e.g., EV battery encapsulation) while ensuring uniform coating thickness.

Ideal For:

Recyclable packaging adhesives,

Marine composite bonding,

Wind turbine blade coatings,

Eco-friendly construction sealants.

Cyclopentanol-Based Coating

Industrial Applications

Sustainable Manufacturing

Cyclopentanol-Based Coating for solar tracker systems

Cyclopentanol-Based Adhesive in recyclable packaging

Transportation

Cyclopentanol-Based Polyurethane seating foams

Cyclopentanol-Based Adhesive Coating for EV motor bonding

Energy Infrastructure

Cyclopentanol-Based Coating on subsea cable connectors

Cyclopentanol-Based Adhesive for wind turbine spar caps

Cyclopentanol-Based Solutions: Advanced Coating & Adhesive Systems

As a sustainable chemistry pioneer, our formulations redefine material performance:

Cyclopentanol-Based Coating for extreme environmental protection

Cyclopentanol-Based Adhesive enabling structural bonding innovation

Cyclopentanol-Based Adhesive Coating merging dual functionality

Cyclopentanol-Based Polyurethane for next-gen elastomers

Packaging

Iron drum packing or ISO tank

Storage and Transport

Store in a cool, ventilated warehouse. Keep away from fire and heat. The storage temperature should not exceed 37℃. Keep the container sealed. Should be stored separately from oxidizer, do not mix storage. Explosion-proof lighting and ventilation facilities are adopted. Do not use mechanical equipment and tools that are prone to spark. The storage area should be equipped with leak emergency treatment equipment and suitable containment materials.

Pictures

Packaging and Shippment

Core Performance Advantages

1. Eco-Conscious Protection

The Cyclopentanol-Based Coating delivers:

70% reduced carbon footprint vs. petrochemical coatings

Saltwater corrosion resistance

UV stability for offshore wind turbine blades

2. Structural Bonding Excellence

Cyclopentanol-Based Adhesive achieves:

25 MPa shear strength on CFRP-aluminum joints

-40°C flexibility for Arctic pipeline repairs

30% faster curing in EV battery module assembly

3. Hybrid Material Innovation

Cyclopentanol-Based Adhesive Coating combines:

Anti-corrosion properties with vibration damping

Seamless metal-to-composite bonding in aerospace

4. Advanced Polymer Chemistry

Cyclopentanol-Based Polyurethane enables:

500% elongation in wearable device components

Hydrolysis resistance in marine engine seals

Strategic Value Proposition

Circular Economy Alignment

Closed-loop recycling for Cyclopentanol-Based Polyurethane waste

Technical Customization

Tailored viscosity for Cyclopentanol-Based Adhesive Coating

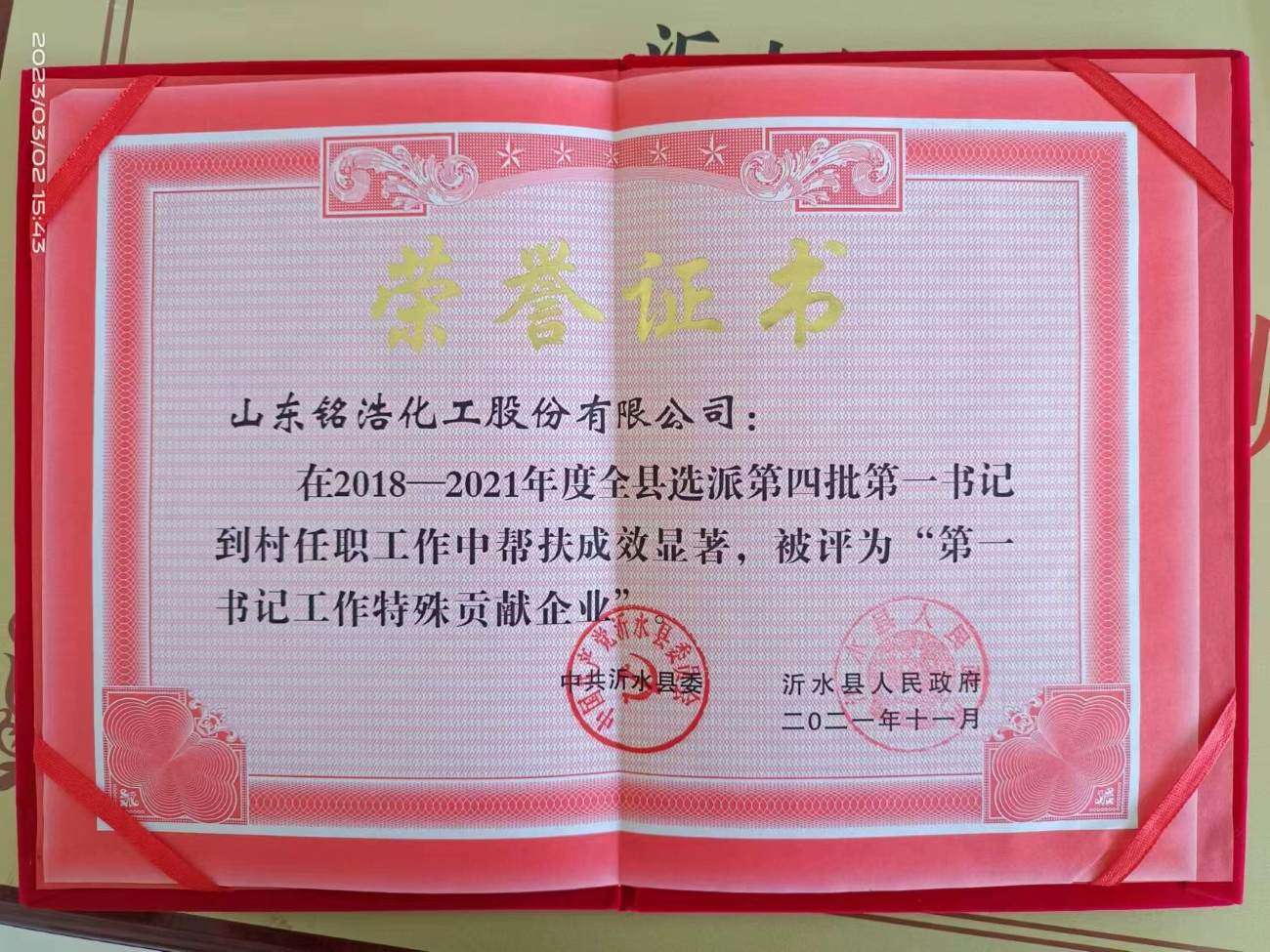

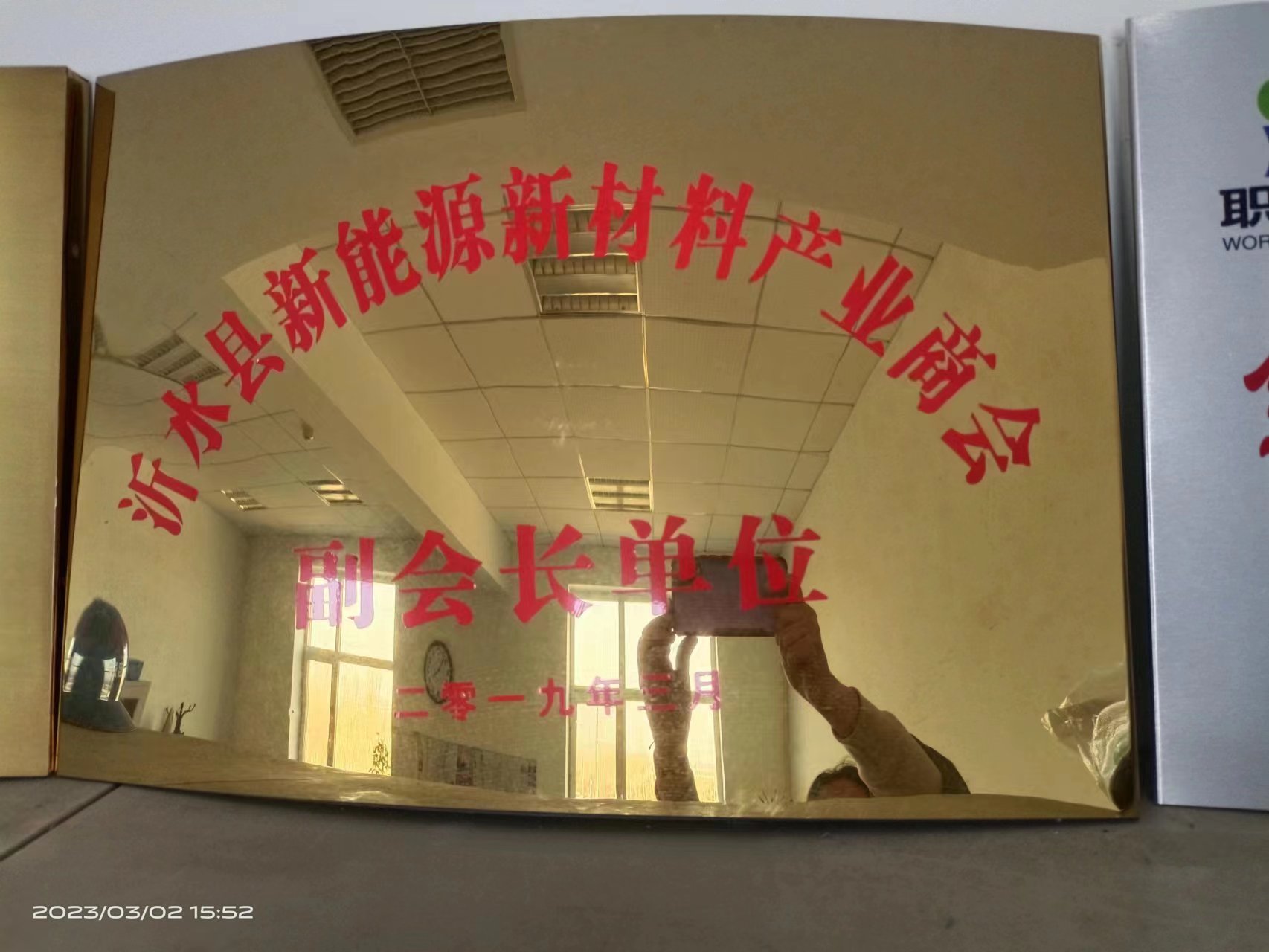

Our advantages

1. Product Diversity: Our product line covers from traditional chemical products to new materials, meeting the needs of different industries.

2. Location Advantage: The company is located in Shandong Province which facilitates coordination and logistics, reducing costs.

3. Production capacity: We have 20 years of production experience and advanced production technology, and a stable production line to ensure that we have sufficient production capacity.

4. Finance and Management: The company has been in operation for many years, with a solid financial foundation and an experienced management team.

5. Customer and Quality: The company's customer-first service and 100% qualified products show that we focus on customer satisfaction and quality control. The company's long-term operation has also enhanced its market reputation.

6. Samples provided

7. OEM service

8. 24 hours service online

Various certificates

FAQ

Q: Are you a factory or trading company?

A: We are manufacturer of some chemical raw materials, we can help buyers to decide which products are there best choice, and all your inquiry will be replyed within 24 hours.

Q: Can your company accept the special requirements of your customers?

A: Of course, we can.

Q: How about your delivery time?

A: Generally, it will take 10 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: How to start orders or make payments?

A: Proforma invoice will be sent first after confirmation of order, enclosed our bank information. Payment by T/T or L/C at sight.

Q: Is there any discount?

A: Of course. The price is negotiable. You will get discount and the most favorable price if you order large quantity goods.

Q: Is there any possible to use my appointed label or package?

A: Yes. If needed, we'd like to use label or package according to your requirement