Cyclopentane Additive For Rubber And Plastic Manufacturing

Brand Minghao

Product origin Linyi, Shandong

Delivery time 10-15 days

Supply capacity 10000 tons

Cyclopentane additives improve rubber and plastic flexibility while reducing VOC emissions, aligning with eco-friendly production mandates.

Parameter

Name | Cyclopentane | |

Synonyms | Pentamethylene | |

CAS | 287-92-3 | |

Chemical formula | C5H10 | |

Molecular mass | 70.1 | |

Melting point | -94℃ | |

Boiling point | 49℃ | |

Flash point | -37℃ | |

Explosion limit | 1.1~8.7% | |

| ||

Test items | Standard | Results |

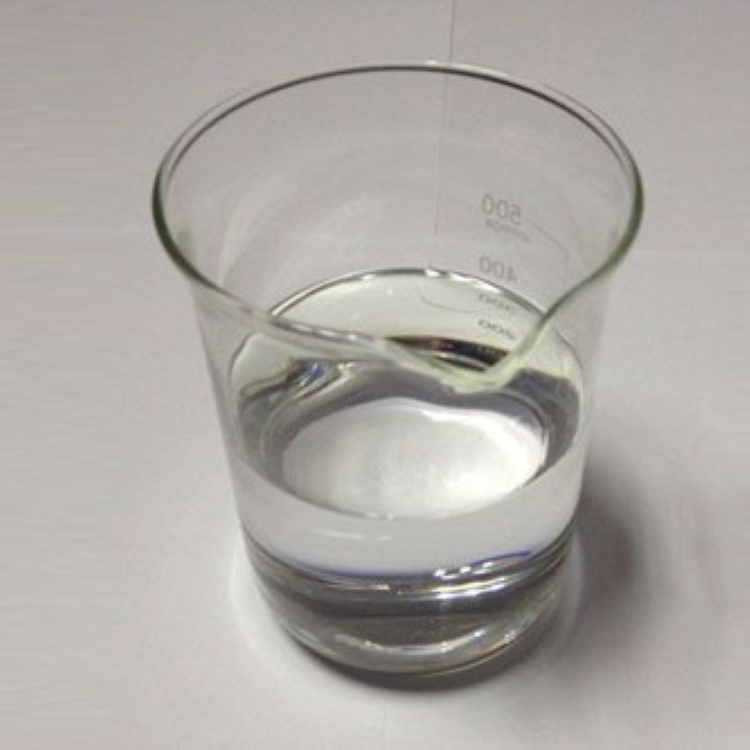

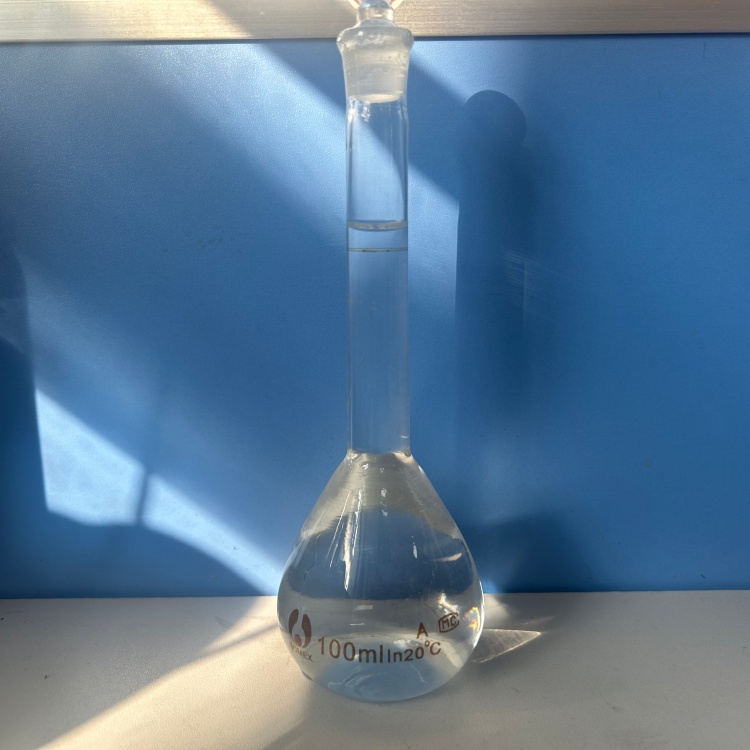

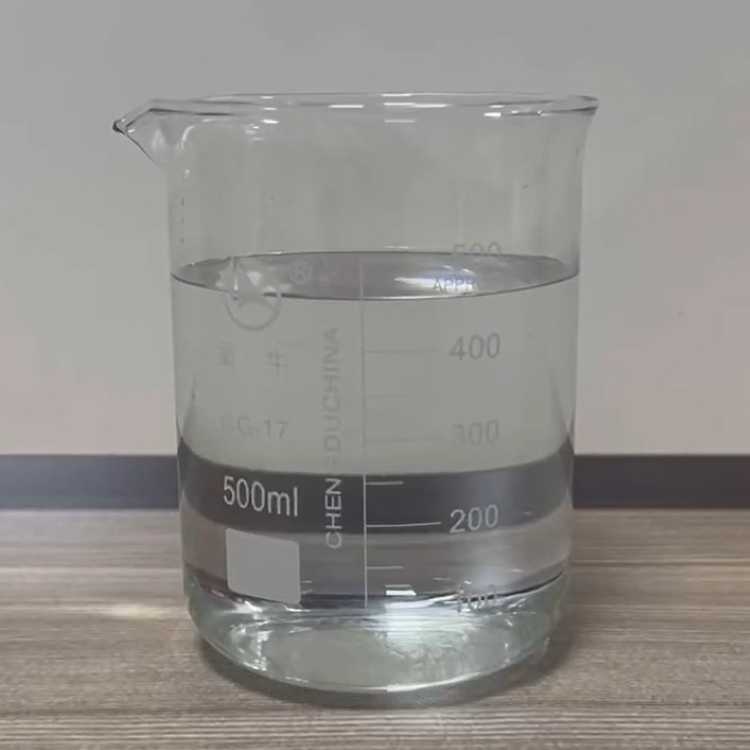

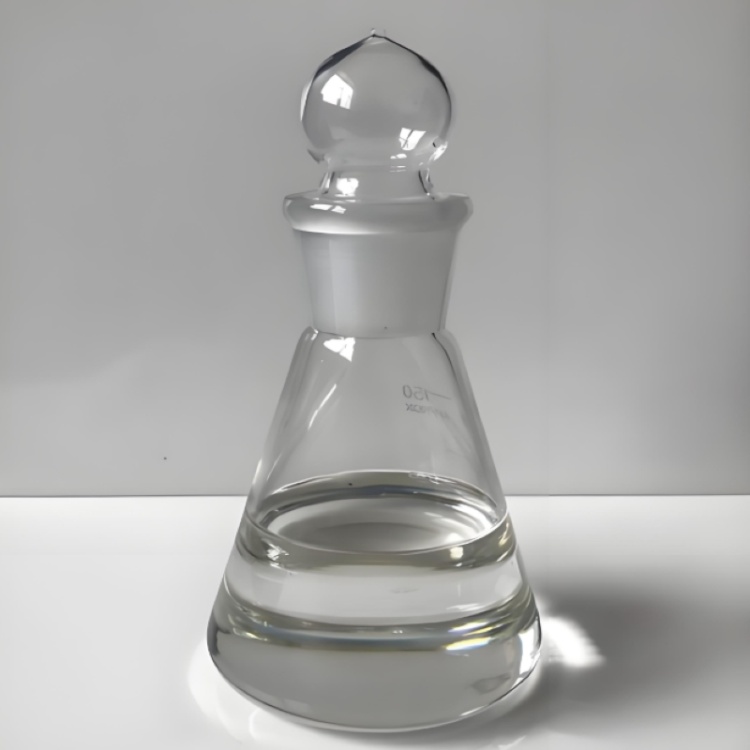

Appearance | Colorless transparent liquid | Colorless transparent liquid |

Cyclopentane content %(m/m) | 99.0min | 99.59 |

Benzene content (mg/Kg) | 1.0max | Not detected |

N-hexane content (mg/Kg) | 10.0max | Not detected |

Naphthalene content (mg/Kg) | 1.0max | Not detected |

Density (g/ml) | 0.751 | 0.751 |

Water content %(m/m) | 0.01max | 0.0033 |

Sulfur content (ug/ml) | 1.0max | 0.10 |

Purpose

Cyclopentane can be used as a standard substance for chromatography analysis, a solvent, an engine fuel, and an azeotropic distillation agent. Additionally, cyclopentane additive for rubber is widely utilized to enhance the flexibility and durability of rubber materials, making it indispensable in rubber production. Similarly, cyclopentane polymer additive improves the properties of polymers, enabling the creation of robust and adaptable materials. Furthermore, cyclopentane additive for plastic manufacturing plays a critical role in optimizing plastic production processes, resulting in plastics with exceptional strength and versatility. The incorporation of cyclopentane additive for rubber and cyclopentane polymer additive demonstrates cyclopentane’s vital contribution to advancing material quality in industries such as automotive and construction. Moreover, cyclopentane additive for plastic manufacturing supports the development of high-performance plastics, while cyclopentane polymer additive enhances polymer durability and processing efficiency. The repeated use of cyclopentane additive for rubber and cyclopentane additive for plastic manufacturing underscores cyclopentane’s broad industrial significance in material science.

Packaging

Iron Drum, Net Weight 149KG/barrel

IOS Tank

Storage and Transport

Storage precautions: Cyclopentane should be stored in a cool, ventilated warehouse, away from fire and heat sources, with the warehouse temperature not exceeding 25°C to ensure its stability as cyclopentane additive for rubber. The container must remain sealed to prevent degradation that could impact its effectiveness as cyclopentane polymer additive. Proper storage is crucial for maintaining cyclopentane’s quality as cyclopentane additive for plastic manufacturing in sensitive industrial applications.

Transportation precautions: Cyclopentane is strictly forbidden to mix and transport with oxidants, edible chemicals, etc., as contamination could diminish its performance as cyclopentane additive for rubber. During transportation, cyclopentane should be protected from exposure to sunlight, rain, and high temperatures to preserve its integrity as cyclopentane polymer additive. When stopping in the middle, cyclopentane should be kept away from fire, heat sources, and high-temperature areas to maintain its effectiveness as cyclopentane additive for plastic manufacturing. These measures are essential to ensure cyclopentane remains suitable for use as cyclopentane additive for rubber, cyclopentane polymer additive, and cyclopentane additive for plastic manufacturing in various industries.

Pictures

Our Advantages

1. Product Diversity: Our product line covers from traditional chemical products to new materials, meeting the needs of different industries.

2. Location Advantage: The company is located in Shandong Province which facilitates coordination and logistics, reducing costs.

3. Production capacity: We have 20 years of production experience and advanced production technology, and a stable production line to ensure that we have sufficient production capacity.

4. Finance and Management: The company has been in operation for many years, with a solid financial foundation and an experienced management team.

5. Customer and Quality: The company's customer-first service and 100% qualified products show that we focus on customer satisfaction and quality control. The company's long-term operation has also enhanced its market reputation.

6. Samples provided

7. OEM service

8. 24 hours service online

Patent Certificates

Packing & Shipping

FAQ

Q: Can you provide detailed specifications for your products, such as chemical composition and applications?

A: Yes, detailed product specifications, including chemical composition and applications, can be provided upon request. Please contact our sales team for more information on specific products.

Q: What payment methods do you accept for international transactions?

A: We accept various payment methods for international transactions, including bank transfers and letters of credit. Please contact our sales team to discuss the most suitable payment options for your order.

Q: Which countries or regions do you currently export to?

A: We currently export our products to multiple regions, including india, Southeast Asia, Central Asia, the Middle East, and South America.

Q: Can I use my own label or packaging?

A: Yes, we can accommodate requests for custom labels or packaging. Please inform our sales team of your preferences.

Q: Why might the quoted price differ from the listed price?

A: Chemical prices fluctuate with market conditions. We aim to provide competitive and transparent pricing based on current market trends